You might have asked in search engines what is pipeline pigging? Drinkwater Products was established in Louisiana in 1987, delivering best-in-class pipeline specialty products for the oil and gas industry. With an unmatched selection of pipeline pigging products and unequaled customer service, Drinkwater Products has become the market leader for successful pipeline maintenance.

What is Pipeline Pigging?

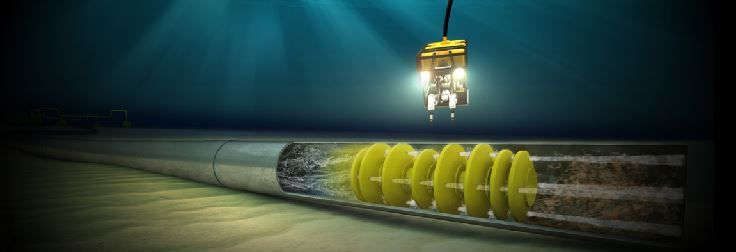

Pipeline pigs are devices that are inserted into and travel throughout the length of a pipeline driven by the product flow.

Why Pig a Pipeline?

Pigs play a major role in two main functions for pipelines. That's why pigging in pipelines and regular maintenance is important.

- That might help to ensure continuous operation by removing any substance which might damage the pipeline process systems and help to prevent the formation of corrosion cells.

- That might help to ensure maximum efficiency by removing any liquid or solid debris in the pipeline which might otherwise build up and restrict the flow.

Pipeline Pigging Applications

The earliest pigs were used simply to remove any large deposits of wax or dirt in order to maintain a flow through the pipeline. Today, pigging is required during each phase in the life of a pipeline – for many different reasons, typically:

During construction

- Removing construction debris from the line

- Acceptance testing (dewatering, drying, gauging, etc.)

- Commissioning

During operation

- Improve flow efficiency

- Solid/liquid debris removal

- Product separation (batching)

- Applying chemical

- Cleaning in preparation of an ILI run

For inspection

- To identify dents, deformations and other ovality changes

- To detect corrosion, cracks, gouging and other metal loss features

- Temperature and pressure recording

- Leak detection

- Wax deposition measurement

- Product sampling

- Mapping

During renovation/rehabilitation

- Gel pigging

- Applying coatings

- Chemical cleaning

- Cleaning for product conversion

Decommissioning

- Product removal

- Pipe-wall cleaning

- Inspecting/testing

- Inert gas/purge pipelines

When considering any pigging application, it should always be remembered that every pipeline is different. They have different diameters, wall thicknesses, flow rates, pressures, temperatures, products, distances and areas of operation. These pipelines are also built by different contractors who have constructed and operated in accordance with different codes and requirements. These pipelines are also owned by several different companies. These companies will have different philosophies and operating procedures. Pig selection should not only rely on accomplishing a goal, but one that keeps the characteristics of the pipeline and its owner in mind.

Drinkwater Products Delivers

Pipeline Maintenance Solutions for Optimal Operation

As an industry-recognized leader in pipeline maintenance, Drinkwater Products specializes in pipeline pigging, measurement and corrosion.

Advantages of using Drinkwater Products:

- Provides the highest quality products, backed by lifetime customer care.

- Offers pipeline pigging products and accessories from a range of manufacturers for your specific application.

- Has a large inventory to provide clients with the right pigging product at an impressive turnaround rate.

- Has earned and maintained a fantastic reputation over 25+ years in business.

Drinkwater Products offers the following pipeline pigging products:

- Foam pigs

- Cast-urethane pigs

- Steel body pigs

- Spheres

- Electromagnetic transmitters and receivers

- Geophones

- Intrusive and non-intrusive pig detectors

Drinkwater Products offers the following services:

- Custom designed pigs

- Maintenance pigging strategies

- Step-up pigging plans

For all your pipeline pigging requirements, get hold of Drinkwater Products today.

Related topics: How Pipeline Pigging Works, Pigging in Pipelines