Evolution® is the next generation isolation gasket platform. EVOLUTION® gaskets offer easy installation, tight sealing, no permeation, hydrotesting isolation, fire-safety and chemical resistance.

It is difficult to predict change with a growing population and increasing energy demands. For oil and gas reserves to meet demand, enhanced recovery and production methods are needed. Steam carbon dioxide, and sometimes sour gases, are moved at higher temperatures, higher pressures, and longer distances than ever before.

It is difficult to predict change with a growing population and increasing energy demands. For oil and gas reserves to meet demand, enhanced recovery and production methods are needed. Steam carbon dioxide, and sometimes sour gases, are moved at higher temperatures, higher pressures, and longer distances than ever before.

Meanwhile, environmental concerns are clamping down on emissions, and we are quickly discovering that traditional gaskets weren't designed to address this. The materials are insufficient to deal with harsh conditions. Glass reinforced epoxy (GRE) gaskets may cause corrosion, pollution, waste, and damage to flanges, which all have serious consequences.

It is difficult to predict what new challenges oil and gas extraction will face in the future. In order to ensure that our gaskets remain reliable, we developed a solution. Evolution gaskets use a proprietary material for the coating of these gaskets to make them highly abrasion and impact resistant. Chemically, the coating is also resistant to H2S, steam, CO, CO2, as well as other chemicals found in oil and gas pipelines.

Evolution® passed API 6FB fire testing in multiple sizes and pressure classes and has a considerable increase in operating temperature over (GRE) products. Additionally, EVOLUTION® gaskets are free from chemical attack and permeation issues.

GRE gaskets may be susceptible to chemical attack, blowout, thermal attack, hydrolysis and emissions, all of which can be dangerous under harsh conditions. EVOLUTION® is different. Enhanced leakage resistance, flange corrosion resistance, and fire safety levels make this a best-in-class product.

With EVOLUTION®, there are no laminations, so it's more likely to resist high pressure than GRE gaskets.

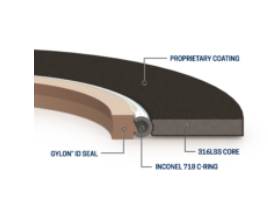

EVOLUTION® can withstand temperatures up to 500°F (260°C)*. Having been tested extensively for safety, the product has been recognized as API 6FB, 3rd Edition Fire Test. Designed to set a new standard in gasketing, the groundbreaking design incorporates five innovative components.

A three millimetre or 18-inch thick 316L stainless steel core encapsulated in a proprietary coating provides isolation, allowing us to eliminate GRE from the design. We provide a c-ring of inconel 718 with a gylon seal, which allows us to provide industry-leading resistance to leakage and flange corrosion. In addition, it is exceptionally fire safe. Quality assurance is just one more characteristic that makes Evolution gaskets stand out.

Drinkwater Products: Proud Distributor of Evolution Gaskets

Pipelines that are not well maintained will eventually corrode and not operate efficiently. A pipeline can suffer corrosion, which can weaken its integrity. The risk of pipeline failure far exceeds the cost of pipeline maintenance. Keeping pipelines in proper repair can save you money.

It's okay! We're here to help! Contact us now to speak to us about evolution gaskets.